Video: Maxim donates robotic learning factory to University College Dublin

Posted 11 December, 2018

- The automated smart factory will help engineering students to understand Industry 4.0 principles.

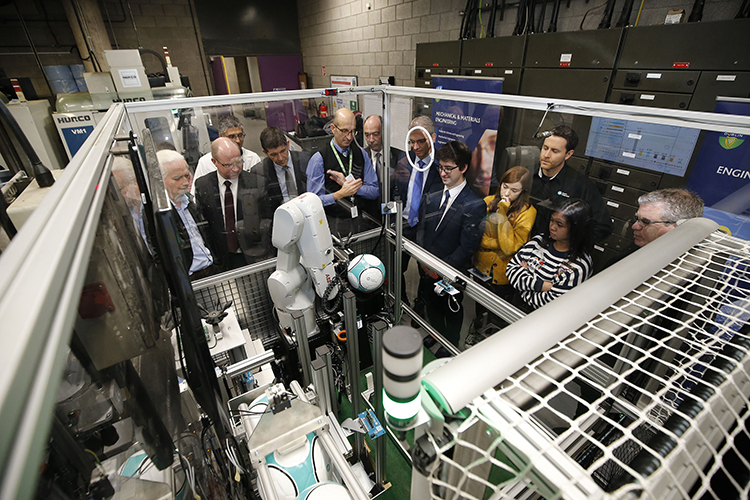

Engineering students at University College Dublin now have the opportunity to gain hands-on experience with Industry 4.0 principles using an automated football factory donated to the University by Maxim Integrated Products.

The smart factory integrates several of the company’s adaptive manufacturing technologies, including the recently announced Go-IO industrial internet of things (IIoT) reference design.

In a world of rapidly evolving production technologies, the donation to the UCD School of Mechanical and Materials Engineering will help the University’s future engineers learn the principles of a smart factory and how to design fully automated and intelligent equipment with self-diagnostic and adaptive capabilities.

“Our football factory has been pivotal in demonstrating the concepts of Industry 4.0 based on the capabilities of our third-generation industrial factory automation chipset that embodies the Go-IO IIoT reference design, most recently at electronica, the world's leading trade fair for electronics,” said Jeff DeAngelis, Managing Director, Industrial & Healthcare Business Unit, at Maxim Integrated.

“We are very happy that we can now pass the factory on to good hands to help educate a new generation of students and prepare them for the technological challenges of the future.”

Jeff DeAngelis, Managing Director, Industrial & Healthcare Business Unit, at Maxim Integrated

The football factory commences with regulation-size footballs and tests them for weight, air-pressure, bounce height and roundness.

An industrial robot handles the footballs, and the entire assembly line is controlled wirelessly by an iPad.

The automated demo showcases the principles of adaptive/flexible manufacturing, where the production system embodies a level of flexibility to react to different environmental conditions, product variations, specification changes or even product options.

UCD students will have the opportunity now to gain hands-on experience with Industry 4.0 principles using the smart football factory

Not only is it optimised to test size five footballs; the smart factory can also be configured on-the-fly to test different-sized footballs.

When different-sized footballs are inserted at random in the production line, the demo factory identifies the product variation and re-adjusts the different sensor calibrations, as well as the robotic software, to process the appropriate-sized balls.

The football factory testing balls for weight, air-pressure, bounce height and roundness at UCD

“This factory gives UCD students as well as our academic staff, particularly those from mechanical, electrical and control engineering and computer science, the opportunity to experiment and learn how to design future production facilities, which are highly connected, increasingly intelligent and even self-aware,” said (opens in a new window)Professor Denis Dowling, UCD School of Mechanical and Materials Engineering and Director of I-Form, the SFI Advanced Manufacturing Research Centre.

“We are very grateful for this donation in the form of a state-of-the-art production facility in a small format and are pleased to be able to deepen our co-operation with Maxim, which has its European headquarters in Dublin.”

By Staff Writers, UCD University Relations

UCD academics on The Conversation

- Opinion: The leap year is February 29, not December 32 due to a Roman calendar quirk – and fastidious medieval monks

- Opinion: Nigeria’s ban on alcohol sold in small sachets will help tackle underage drinking

- Opinion: Nostalgia in politics - Pan-European study sheds light on how (and why) parties appeal to the past in their election campaigns